Video Analytics – Egg Box Quality Inspection Using AI

The Context

In high-volume food packaging industries, especially with fragile goods like eggs, ensuring product integrity during high-speed packing is critical. Manual inspection methods often lead to inconsistencies, labour inefficiencies, and missed defects.

A leading manufacturing client needed a reliable quality control system to automate the inspection of egg boxes on a high-speed production line. The aim was to achieve consistent detection of cracks, missing eggs, and orientation errors in real time without slowing down the packaging process

The Challenge

- The client’s traditional inspection process was entirely manual, which resulted in human fatigue and inconsistent quality detection.

- Defects like cracks, improperly placed eggs, or missing units were occasionally overlooked, leading to customer complaints and increased returns.

- Maintaining inspection accuracy at production speeds exceeding 150 trays per minute was a critical bottleneck.

The client lacked a system that could adapt to real-time defect classification without disrupting existing infrastructure

Our Solution

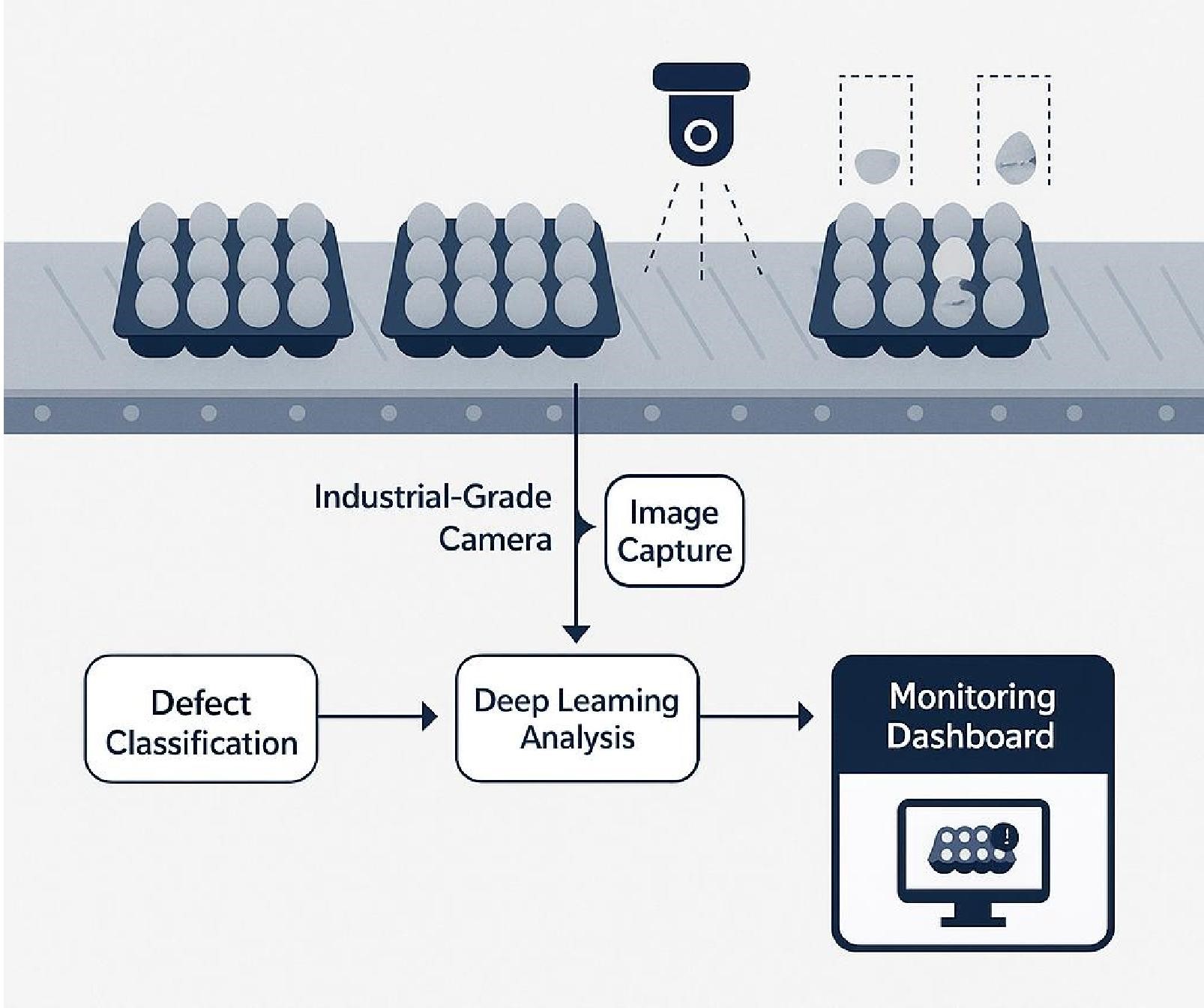

PrimeMover Solutions developed DefectXpert, an AI-powered machine vision system tailored for real-time inspection in high-speed egg box packaging lines.

The system uses industrial-grade cameras paired with deep learning models to identify visual anomalies on each tray. The captured images are processed in real time by object detection and defect classification algorithms. The entire workflow is optimized for minimal latency and can be integrated seamlessly into existing conveyor systems.

Key Features of DefectXpert:

- Real-Time Defect Detection: Identifies defects like cracks, missing eggs, dirt spots, and orientation mismatches.

- Seamless Line Integration: Operates at production speeds without needing to slow down the line or modify existing equipment.

- Automated Alerts and Sorting: Flags defective trays and integrates with rejection

- AI-Powered Classification: Learns from new defect patterns over time, ensuring continuous improvement.

- Dashboard & Analytics: Central interface for supervisors to monitor performance and defect trends in real time.

Impact & Result

By deploying DefectXpert, the client achieved:

- Over 95% accuracy in defect identification at high throughput speeds

- Elimination of manual inspection, reducing labour costs and improving consistency

- Zero disruption to operations with plug-and-play adaptability

- Defect analytics enabling process improvements and predictive maintenance

- Improved product quality, leading to greater customer satisfaction

Conclusion

At PrimeMover Solutions, we continue to advance AI-based visual systems that transform manufacturing operations. Our solutions are built for scalability, precision, and reliability across various industrial contexts — from food packaging to complex assembly lines. DefectXpert reflects our commitment to delivering AI innovations that drive quality, efficiency, and competitive advantage